Recommended maximum hours of use in hours/day.

9.505-250.0

20 AMP THREE PHASE

Operating Pressure - 435 - 2320 PSI

Maximum Pressure - 2755 PSI

Max. feed temperature - 70°C

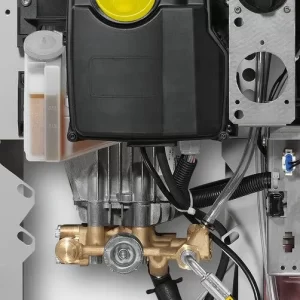

10m steel braided high pressure hose, Easy-press trigger gun with soft grip insert, 1050mm spray lance, manual triple nozzle (0°,25°,40°), anti-twist AVS, brass pump.

Pre-equipped for a detergent inlet, prepared for servo control and/or remote control

Recommended maximum hours of use in hours/day.

9.505-255.0

20 AMP THREE PHASE

Operating Pressure - 580 - 2610 PSI

Maximum Pressure - 3045 PSI

Max. feed temperature - 70°C

10m steel braided high pressure hose, Easy-press trigger gun with soft grip insert, 1050mm spray lance, manual triple nozzle (0°,25°,40°), anti-twist AVS, brass pump.

Pre-equipped for a detergent inlet, prepared for servo control and/or remote control

Recommended maximum hours of use in hours/day.

9.505-265.0

20 AMP THREE PHASE

Operating Pressure - 435 - 2320 PSI

Maximum Pressure - 2755 PSI

Max. feed temperature - 85°C

10m steel braided high pressure hose, Easy-press trigger gun with soft grip insert, 1050mm spray lance, manual triple nozzle (0°,25°,40°), anti-twist AVS, brass pump.

Pre-equipped for a detergent inlet, prepared for servo control and/or remote control

Recommended maximum hours of use in hours/day.

9.505-272.0

20 AMP THREE PHASE

Operating Pressure - 580 - 2610 PSI

Maximum Pressure - 3045 PSI

Max. feed temperature - 85°C

10m steel braided high pressure hose, Easy-press trigger gun with soft grip insert, 1050mm spray lance, manual triple nozzle (0°,25°,40°), anti-twist AVS, brass pump.

Pre-equipped for a detergent inlet, prepared for servo control and/or remote control

After the machine's timer function is switched off, the high-pressure unit is still pressurised. The attachment kit reduces the pressure in the system, thus ensuring protection of the pressurised components. The pressure relief attachment kit is recommended particularly if there are often longer intervals between the individual usage intervals.

After the machine's timer function is switched off, the high-pressure unit is still pressurised. The attachment kit reduces the pressure in the system, thus ensuring protection of the pressurised components. The pressure relief attachment kit is recommended particularly if there are often longer intervals between the individual usage intervals.

The attachment kit prevents scaling in the system through the continuous dosage of liquid softeners. Damage to the pump and other key components as a result of calcification can be avoided. It is recommended for high inlet temperatures and the ST-H version.

The attachment kit prevents scaling in the system through the continuous dosage of liquid softeners. Damage to the pump and other key components as a result of calcification can be avoided. It is recommended for high inlet temperatures and the ST-H version.

The kit enables the control of cleaning agent injection by remote control directly at the supply point. The advantage compared with the low-pressure variant lies in the fact that no changing of the nozzle is necessary to apply the cleaning agent. The "remote control preparation" is recommended especially for supply points with frequently changing users, since no changeover at the nozzle which needs an explanation is required here, for operation by coin remote control and for cleaning tasks which require high pressure.

The kit enables the control of cleaning agent injection by remote control directly at the supply point. The advantage compared with the low-pressure variant lies in the fact that no changing of the nozzle is necessary to apply the cleaning agent. The kit is recommended especially for supply points with frequently changing users, since no changeover at the nozzle which needs an explanation is required here, for operation by coin remote control and for cleaning tasks which require high pressure. The variant with two cleaning agents is suitable, for example, for more complex cleaning tasks, distant supply points or for car cleaning.